1

/

of

1

Manufactured by MITSUI ELASTOMERS SINGAPORE PTE LTD

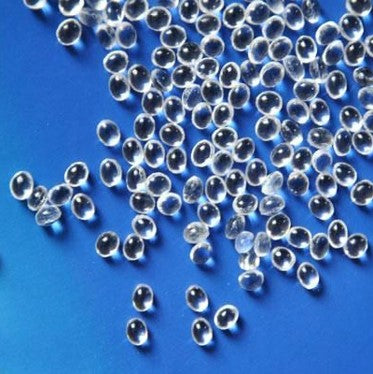

TAFMER™ DF640

TAFMER™ DF640

The TAFMER™ DF of ethylene based copolymers is used to lower Heat Seal Initiation Temperature (HSIT)

General characteristics attributed to TAFMER™:

• Low Melting Point for lowering Heat Seal Initiation Temperature (HSIT)

• Low Young’s Modulus for Softness and Flexibility

• Low Crystallinity for Transparency

• Low Glass Transition Temperature for Low Temperature Impact Resistance

• Miscible with PE and Compatible with PP for Adhesion Strength Control

In PE blown film, it is used to lower HSIT, improve transparency and adhesion strength to PP.

Loading...

- Choosing a selection results in a full page refresh.

- Opens in a new window.